Rod Out Tools

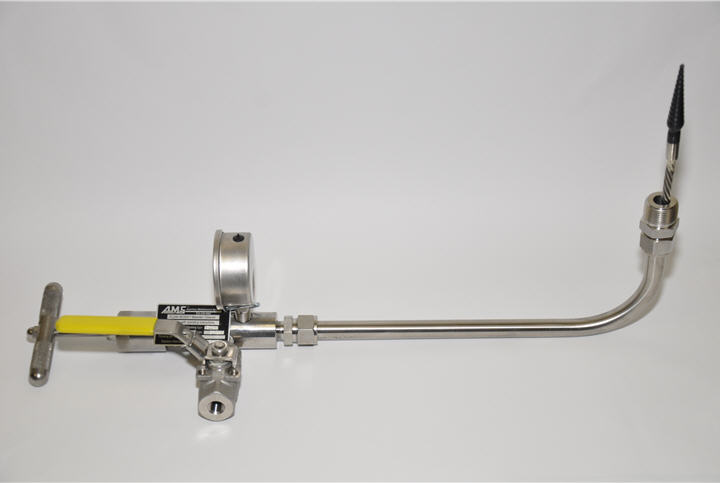

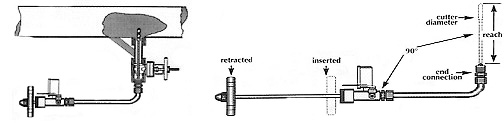

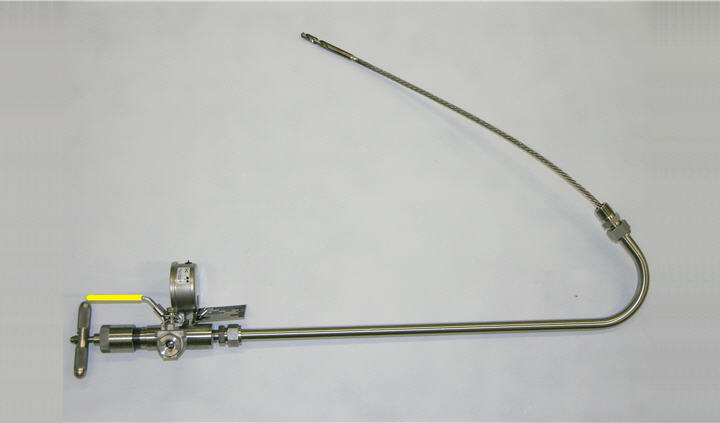

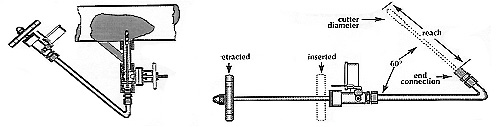

Rod out tools or Flow Boss™ Cleaners allow clogged bleeder, vent and instrument tap valves to be cleaned safely and efficiently while containing process material and preventing worker exposures. These patented tools eliminate the hazards of dangerous fires, spills and vapor releases while performing these tasks. Parts for these Flow Boss™ bleeder cleaners can be replaced in the field, ending the need for factory maintenance. (also called the Flow Boss™ bleeder cleaner, angleworm bleeder cleaner, rod out device, tap cleaner, orifice tap cleaner or bleeder reamer). All models (Patent No. 8,584,296).

FREE FLOW BOSS™ brochure CLICK HERE

Available in three styles:

Angle 90

Angle 60

Straight

Available Field Replacement Parts – End Most Factory Repairs

All Three designs are shown below. Available to fit your female NPT process connections in 1/4″, 1/2″, 3/4″, 1″ MNPT’s

Rod out tools are the only safe device available to clean clogged instrument taps, drain valves, manifolds and orifice taps. Available in diameters of from 1/8″ up to 5/8″ and in lengths from 7 inches to 72 inches with end connections from 1/4″ NPT to 1″ NPT. Never again use a dangerous contraption that has no pressure gauge or vent valve to rod out valves and taps. The standard rod out device is the type 1 unless otherwise selected below

Type 1,0-14 pH,700 deg F / 370 C, PSI 600 / 40 BAR (graphite)

Type 2, 0-14 pH, 350 deg F / 175 C, PSI 600 / 40 BAR (TFE)

Type 3, 0-14 pH, 1000 deg F / 535 C, PSI 1000 / 70 BAR (Graphoil)

Note – Available in pressures up to 3000 psi ( 210 BAR )

Straight Bleeder Cleaners

![straight[1]](http://www.cleanvalve.com/files/straight.jpg)

| Std MNPT | Description | Drill Dia.(in) | Drill Dia.(mm) | Work Depth (in) | Work Depth (mm) | Model | ||||||

| 1/4″ | Straight | 5/32″ | 4mm | 12″ | 30cm | 0750-L-12 | ||||||

| 1/4″ | Straight | 5/32″ | 4mm | 7″ | 17cm | 0750-L-7 | ||||||

| 1/4″ | Straight | 7/32″ | 5mm | 12″ | 30cm | 1650-L-12 | ||||||

| 1/4″ | Straight | 7/32″ | 5mm | 7″ | 17cm | 1650-L-7 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 12″ | 30cm | 2550-L-12 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 7″ | 17cm | 2550-L-7 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 48″ | 120cm | 4350-L-48 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 36″ | 90cm | 4350-L-36 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 24″ | 60cm | 4350-L-24 | ||||||

| 1/4″ | Straight | 1/4″ | 6.5mm | 18″ | 45cm | 4350-L-18 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 12″ | 30cm | 3450-L-12 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 7″ | 17cm | 3450-L-7 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 48″ | 120cm | 5250-L-48 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 36″ | 90cm | 5250-L-36 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 24″ | 60cm | 5250-L-24 | ||||||

| 1/2″ | Straight | 3/8″ | 9.5mm | 18″ | 45cm | 5250-L-18 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 84″ | 210cm | 6150-L-84 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 72″ | 180cm | 6150-L-72 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 60″ | 150cm | 6150-L-60 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 48″ | 120cm | 6150-L-48 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 36″ | 90cm | 6150-L-36 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 24″ | 60cm | 6150-L-24 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 18″ | 45cm | 6150-L-18 | ||||||

| 3/4″ | Straight | 1/2″ | 13mm | 12″ | 30cm | 6150-L-12 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 84″ | 210cm | 7050-L-84 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 72″ | 180cm | 7050-L-72 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 60″ | 150cm | 7050-L-60 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 48″ | 120cm | 7050-L-48 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 36″ | 90cm | 7050-L-36 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 24″ | 60cm | 7050-L-24 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 18″ | 45cm | 7050-L-18 | ||||||

| 1″ | Straight | 5/8″ | 16mm | 12″ | 30cm | 7050-L-12 |

Angle 90 Bleeder Cleaners

| Std MNPT | Description | Drill Dia.(in) | Drill Dia.(mm) | Work Depth (in) | Work Depth (mm) | Model | ||||||

| 1/4″ | Angle 90 | 1/4″ | 6.5mm | 24″ | 60cm | 2500-L-24 | ||||||

| 1/4″ | Angle 90 | 1/4″ | 6.5mm | 18″ | 45cm | 2500-L-18 | ||||||

| 1/4″ | Angle 90 | 1/4″ | 6.5mm | 12″ | 30cm | 2500-L-12 | ||||||

| 1/4″ | Angle 90 | 1/4″ | 6.5mm | 7″ | 17cm | 2500-L-7 | ||||||

| 1/2″ | Angle 90 | 3/8″ | 9.5mm | 24″ | 60cm | 3400-L-24 | ||||||

| 1/2″ | Angle 90 | 3/8″ | 9.5mm | 18″ | 45cm | 3400-L-18 | ||||||

| 1/2″ | Angle 90 | 3/8″ | 9.5mm | 12″ | 30cm | 3400-L-12 | ||||||

| 1/2″ | Angle 90 | 3/8″ | 9.5mm | 7″ | 17cm | 3400-L-7 |

Angle 60 Bleeder Cleaners

| Std MNPT | Description | Drill Dia.(in) | Drill Dia.(mm) | Work Depth (in) | Work Depth (mm) | Model | ||||||

| 1/4″ | Angle 60 | 1/4″ | 6.5mm | 24″ | 60cm | 4300-L-24 | ||||||

| 1/4″ | Angle 60 | 1/4″ | 6.5mm | 18″ | 45cm | 4300-L-18 | ||||||

| 1/2″ | Angle 60 | 3/8″ | 9.5mm | 24″ | 30cm | 5200-L-24 | ||||||

| 1/2″ | Angle 60 | 3/8″ | 9.5mm | 18″ | 17cm | 5200-L-18 |

Specifications of components: pressure gauge, glycerine filled, constructed of 316 Stainless Steel, for restrictions refer to ASME B40.1. Fittings & connectors, constructed of 316 Stainless Steel conform to ANSI B36.10, ANSI B1.20.1, MIL-P-7105 B, barstock material ASME SA479. Manufactured to API 570, ASME B31.3. All components supplied conform to ANSI, ASME, ASTM and ISO-9002

Note. If you cannot locate the correct size or model rod out tools above see “Contact Us” on this page.